Service MedtecLIVE 2024

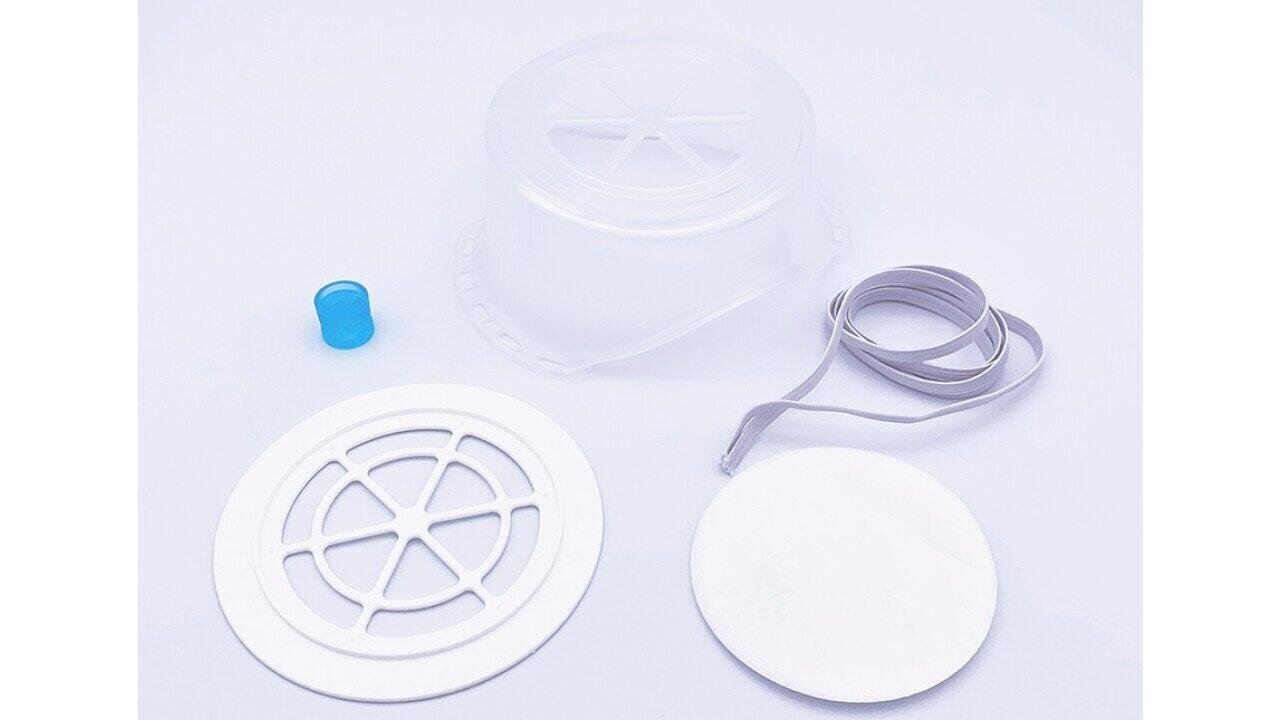

From Prototpying to Serial Production

We prefer to accompany you from the very beginning of your development process. From the individual silicone component to the finished assembly - but always with the right focus on the overall solution.