Automated production of hybrid parts

You can save weight and costs with hybrid parts, as plastic is much cheaper than metal. Automated production makes the whole process even more profitable for the customer.

The Background

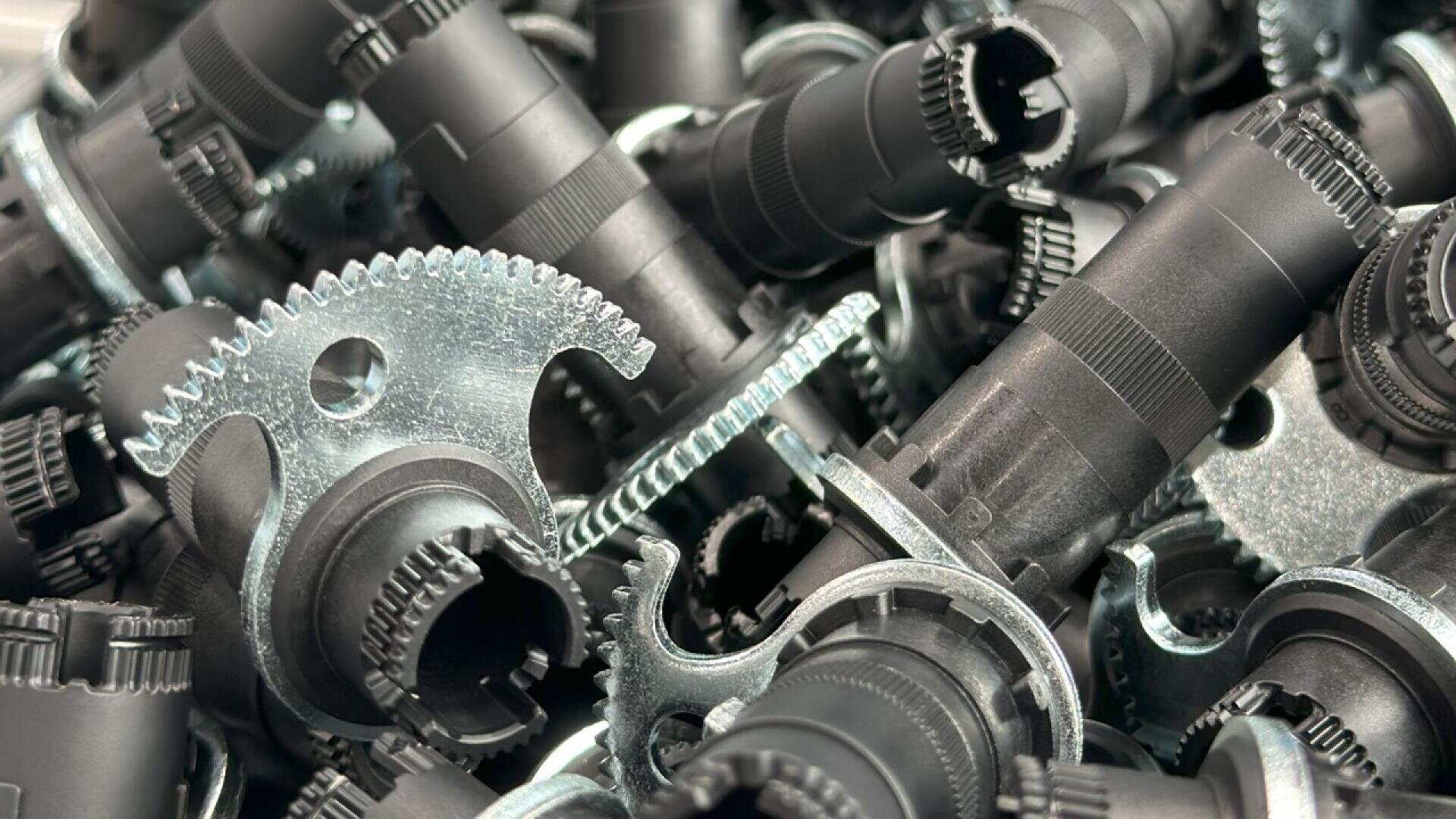

Originally, the segments were inserted manually by a person at the machine. By programming a 5-axis robot and producing a suitable handling system in-house, we were able to eliminate this manual labor in order to produce more cost-efficiently and therefore more competitively.

The metal segment is overmoulded with a 30% glass fiber reinforced polyamide, making it lighter and cheaper than the original metal product. The plastic has high strength and rigidity as well as high impact strength and the requirements for the finished part are therefore met.

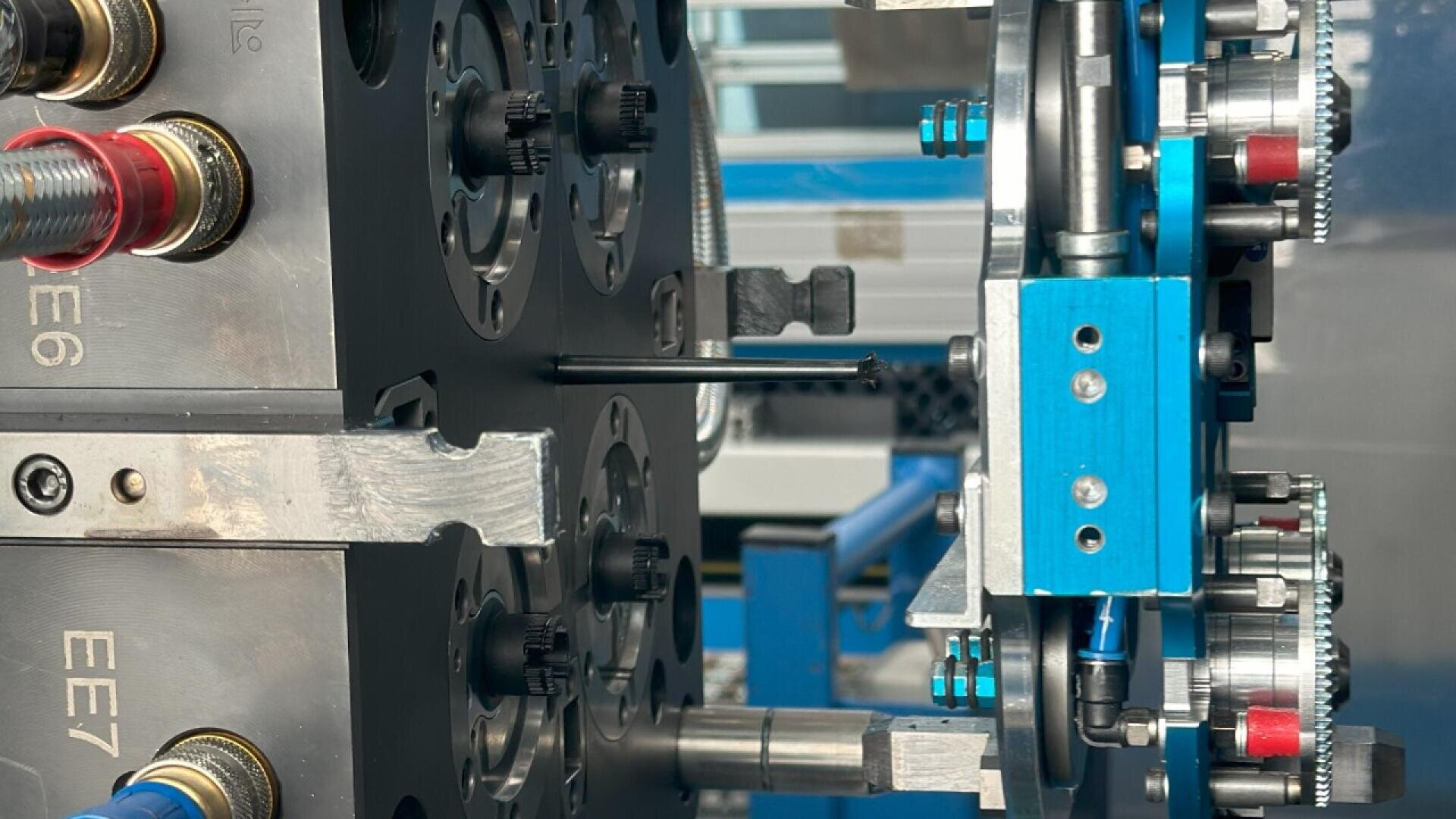

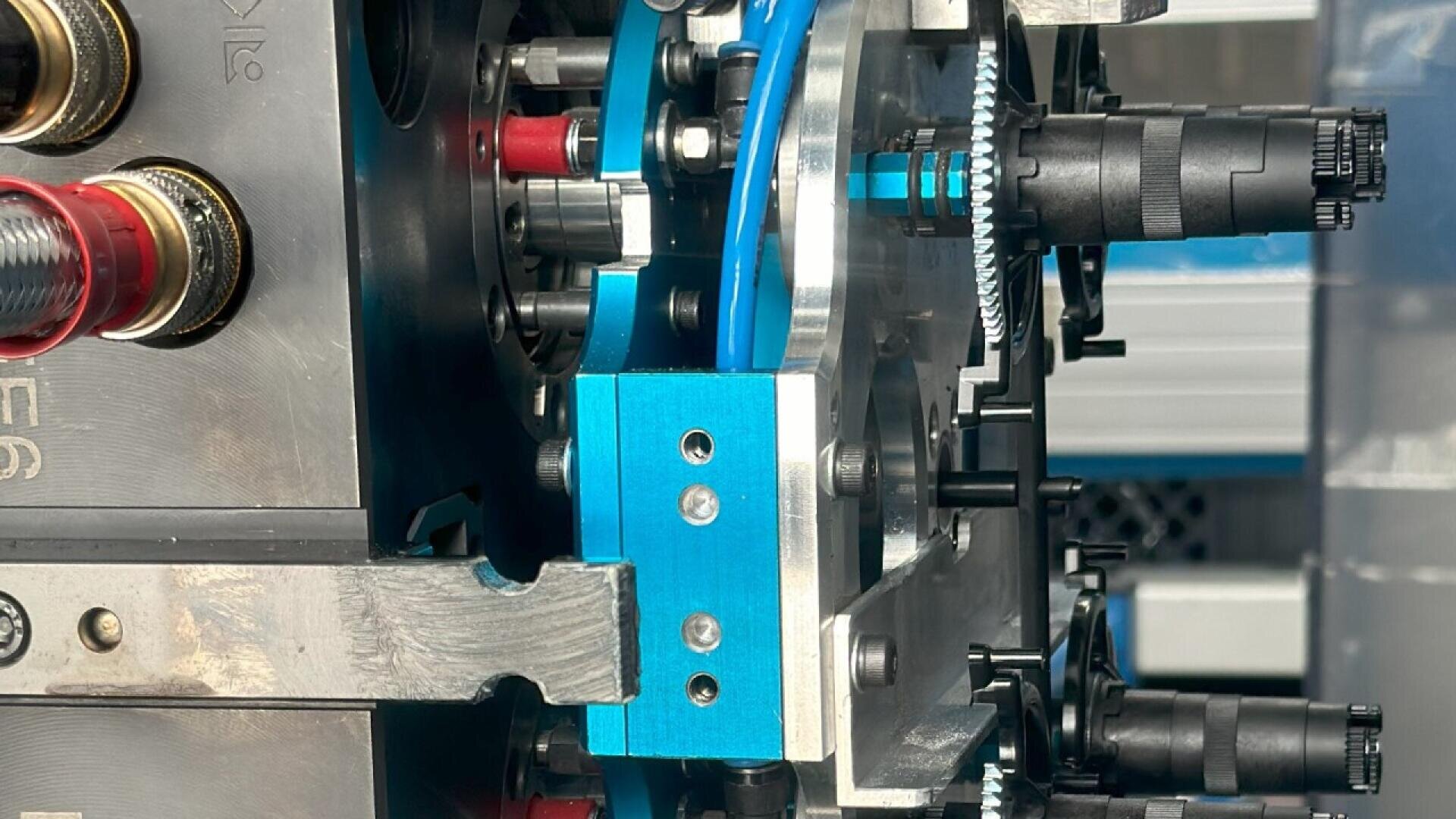

The process

The robot picks the segments prepared in a rack and automatically assembles the two-sided gripper. At the end of the injection cycle, the gripper moves between the mold plates and first removes the finished overmolded parts. The gripper then turns around its own axis and loads the mold with fresh segments. The process can restart while the gripper places the finished parts next to the machine and picks up new segments.

This is not only a pleasure for our customers, but also for our valued employees, who appreciate the challenge of new programming.