Best practice MedtecLIVE 2024

Clear to clear - laser welding without colorant

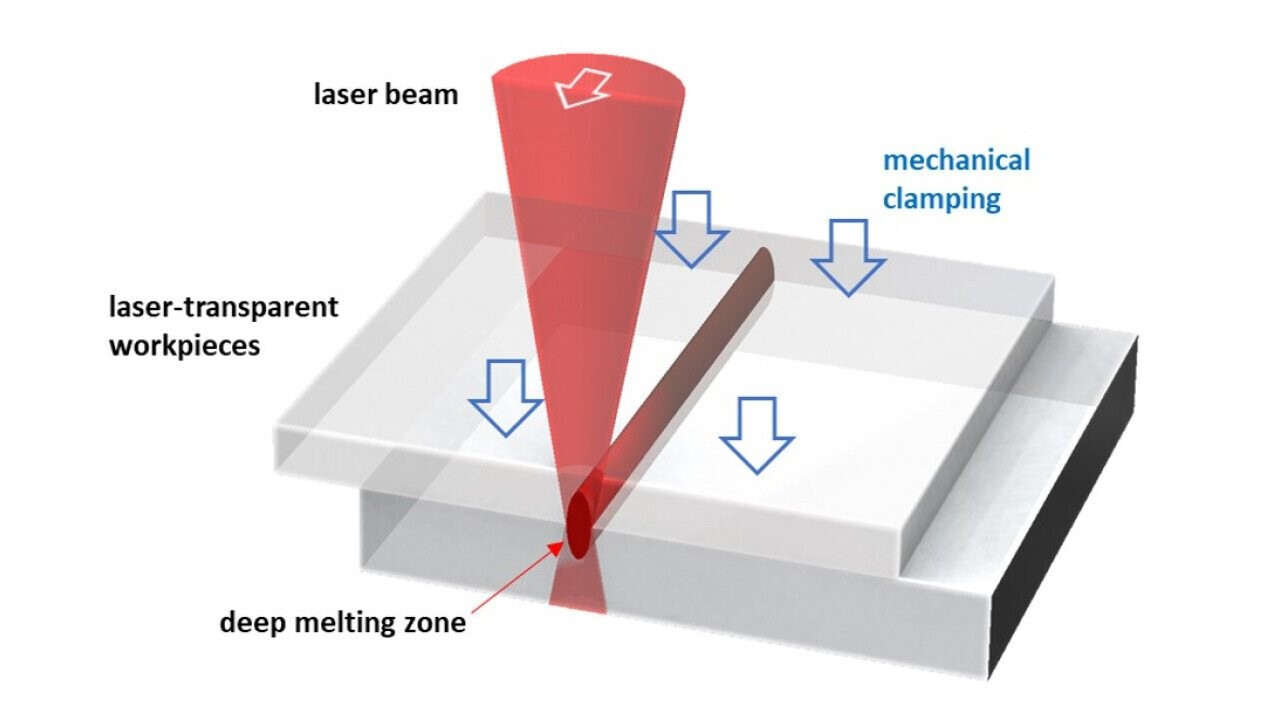

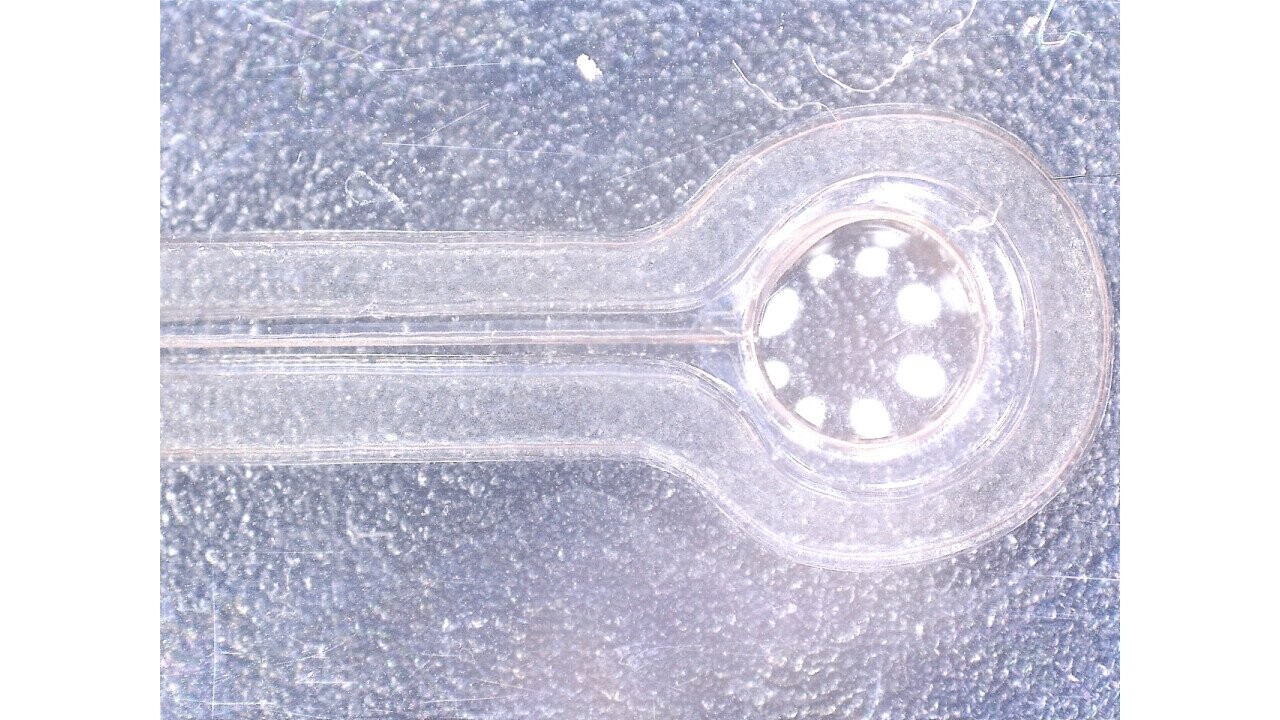

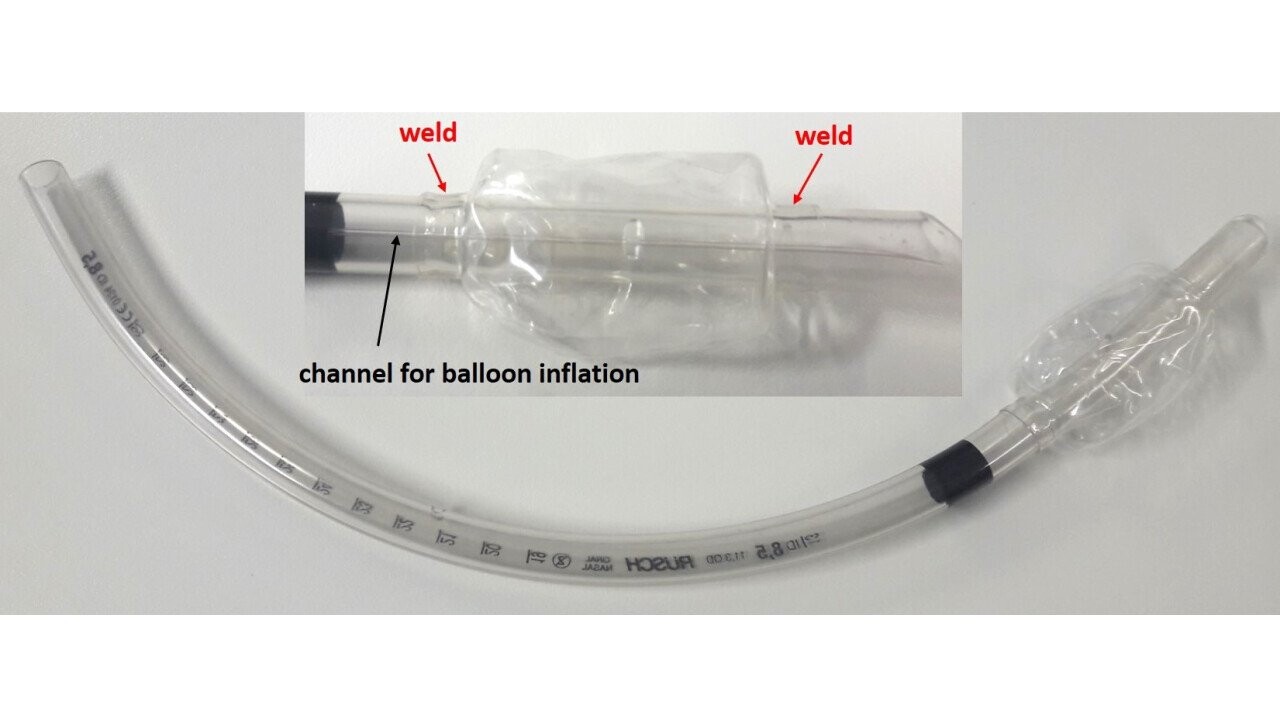

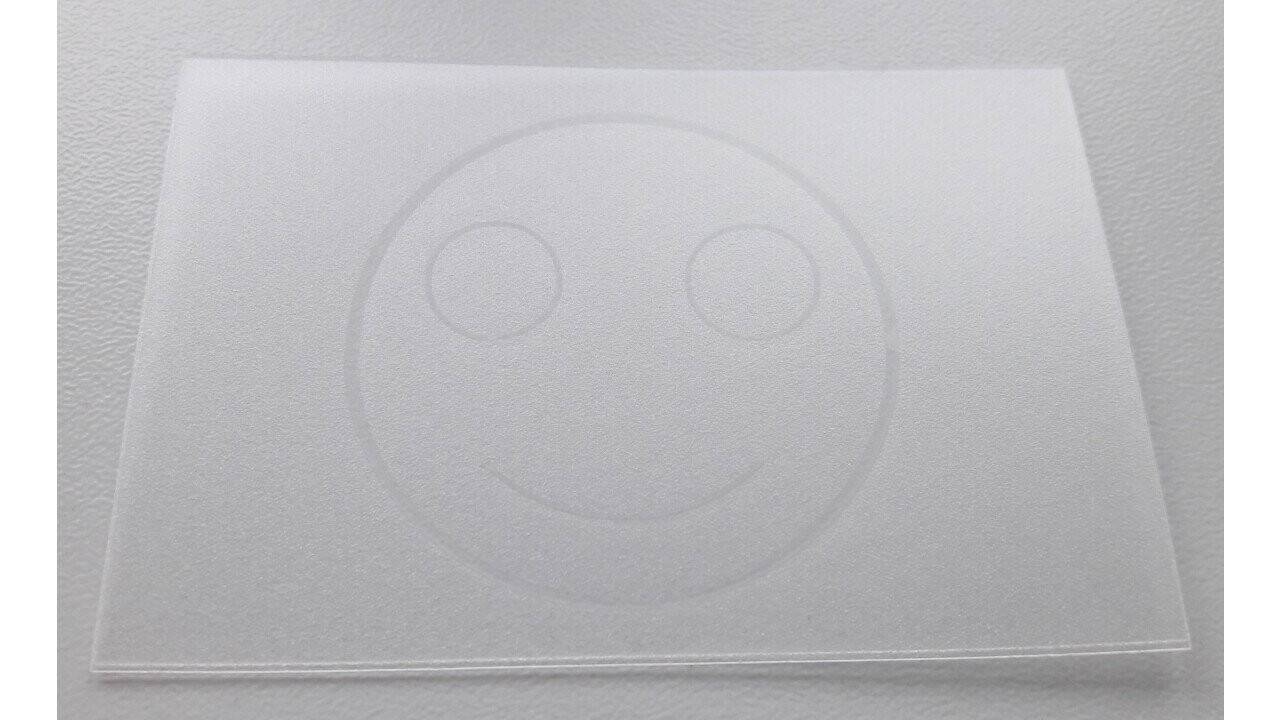

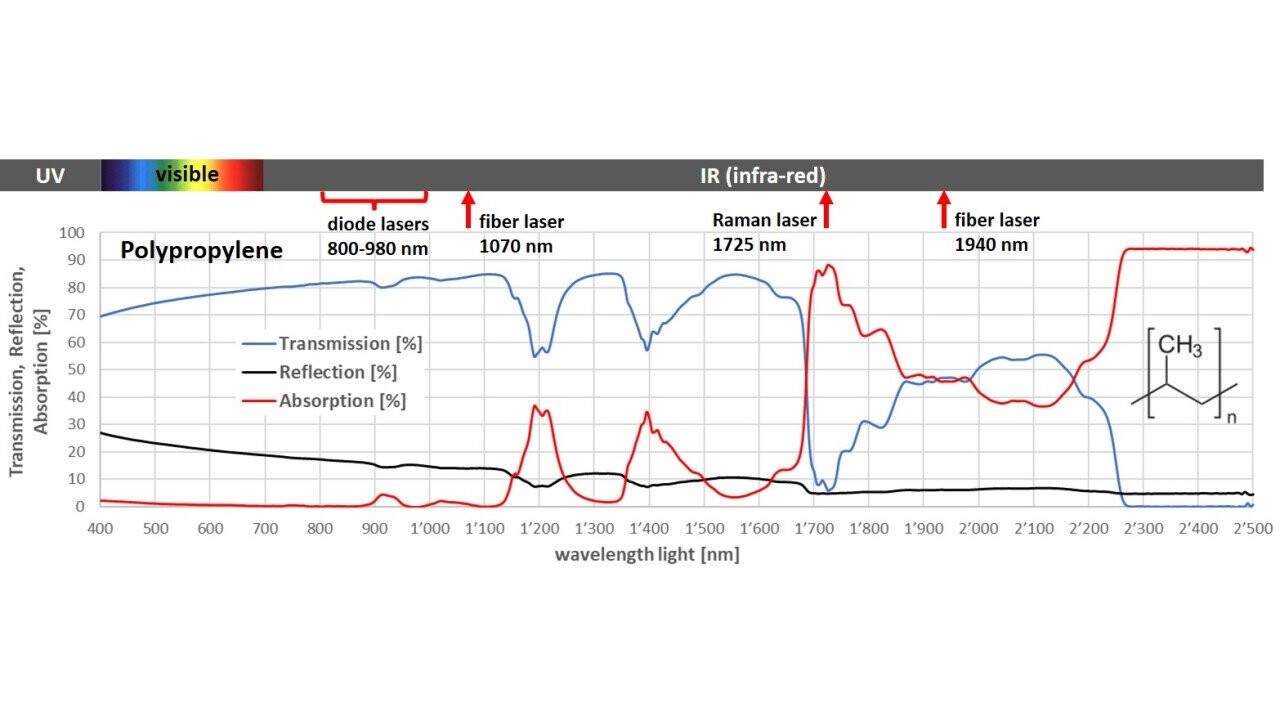

Also transparent plastics without any added colorant can be welded by laser. An extra certification of the plastics additives can be avoided. The standard wavelengths for welding with laser at 800-1'100 nm are changed and adapted to the employed type of plastics.