For your product developments, you have almost unlimited project planning and production options for a wide range of applications. Whether micro injection molding, filling systems, assembly, printing or packaging: here your wishes for the perfect medical product can be realized.

Bundled expertise and diversity in synergy

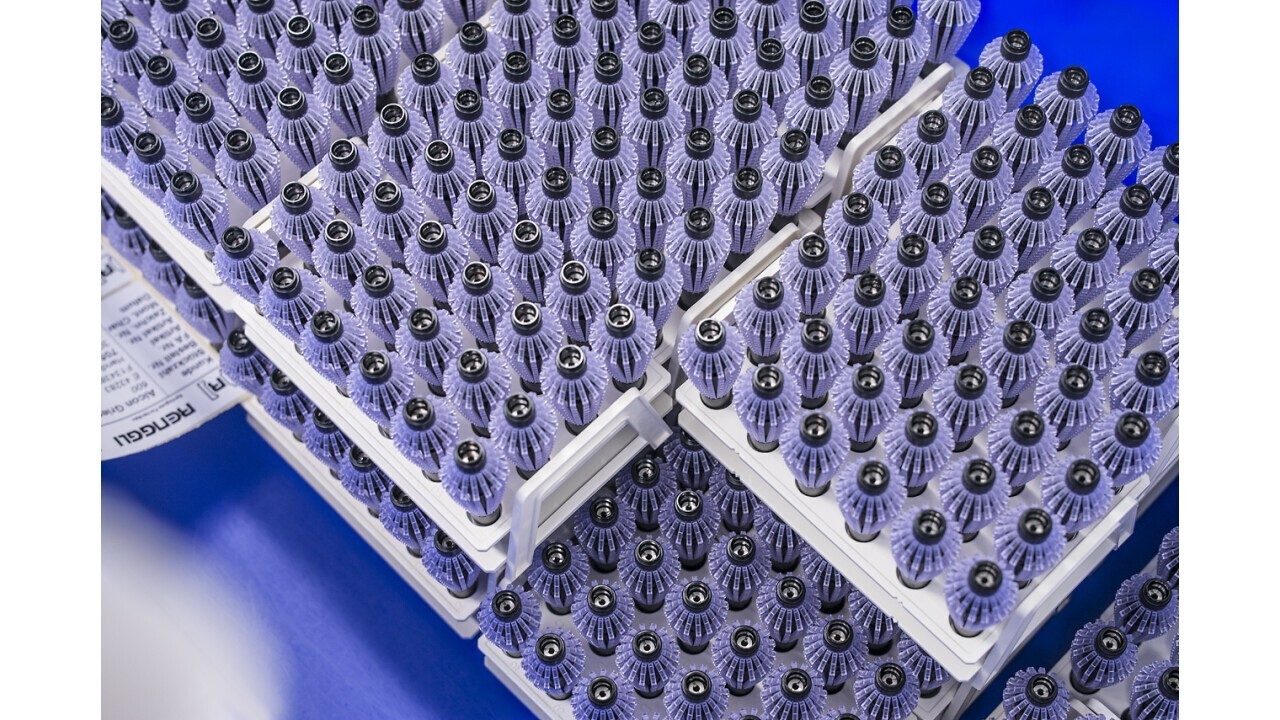

In addition to development and project planning, the TT medic companies also offer design and toolmaking for the existing total of over 60 injection molding machines - including micro injection molding and injection molding in clean rooms.

The teams actively support you in the areas of project management, risk management, feasibility studies, part design, mold making, production automation, process validation and measurement technology.

You also benefit from the entire range of post-processing of plastic parts:

This includes in particular: automation (e.g. of check valves), assembly into entire assemblies and hose systems as well as types of labeling such as pad printing or laser labeling.

Validated joining techniques such as gluing or ultrasonic welding allow your customer-specific products to become complex functional parts, such as valves.

Do you need bottled media? We can also master this challenge:

In a defined cleanroom environment, liquid bulk media can be transferred into syringes or containers according to customer specifications, or granular media into smaller containers.

In total, over 1200 m² of cleanroom space is available to you, from ISO Class 6 to ISO Class 8.