Best practice MedtecLIVE 2024

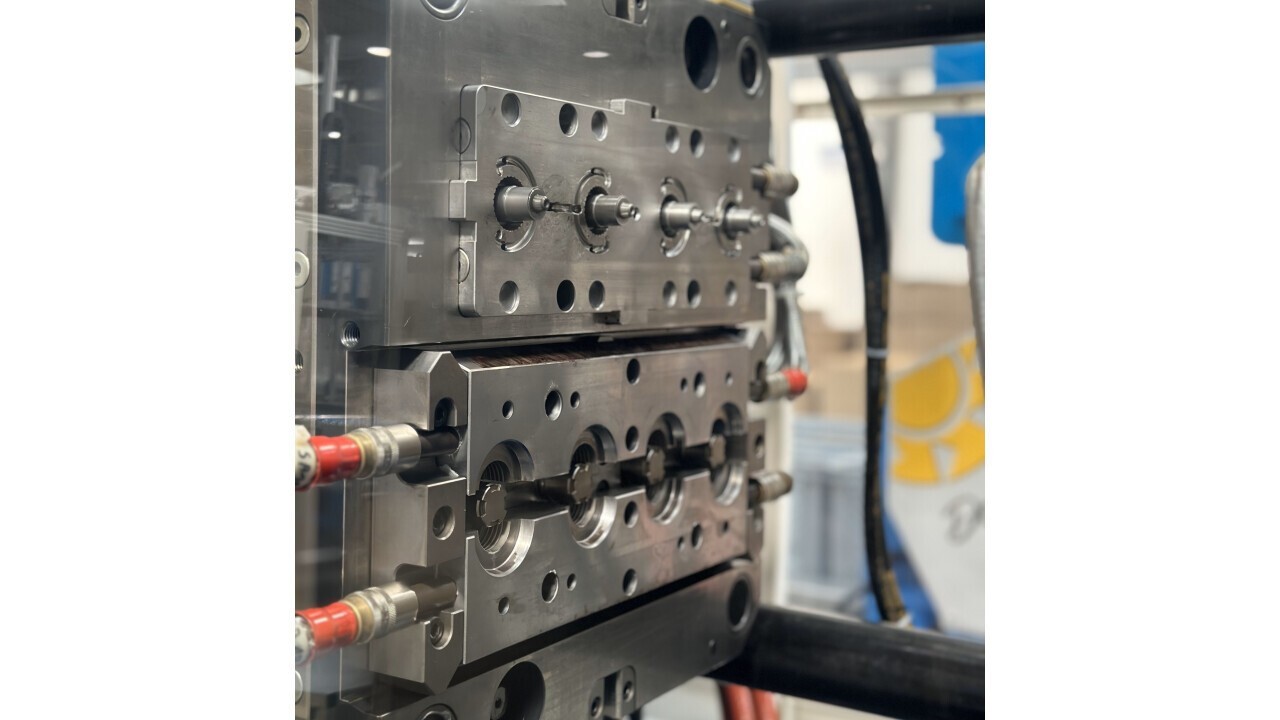

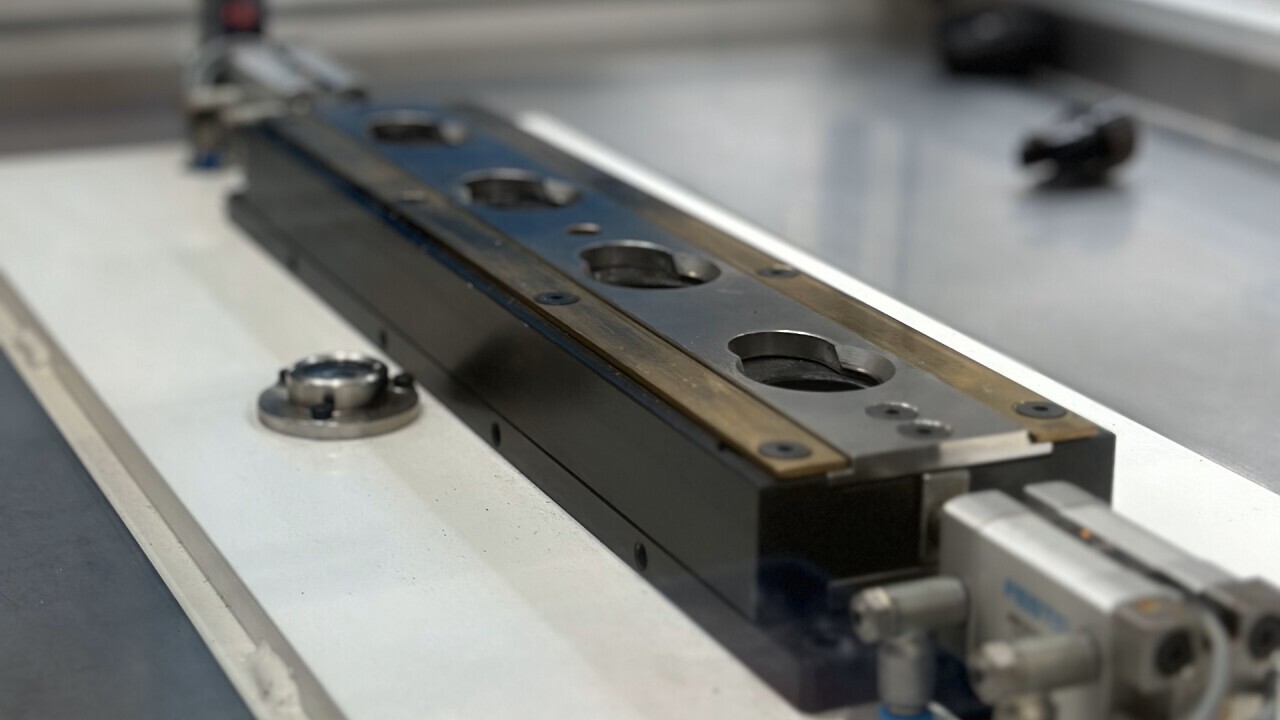

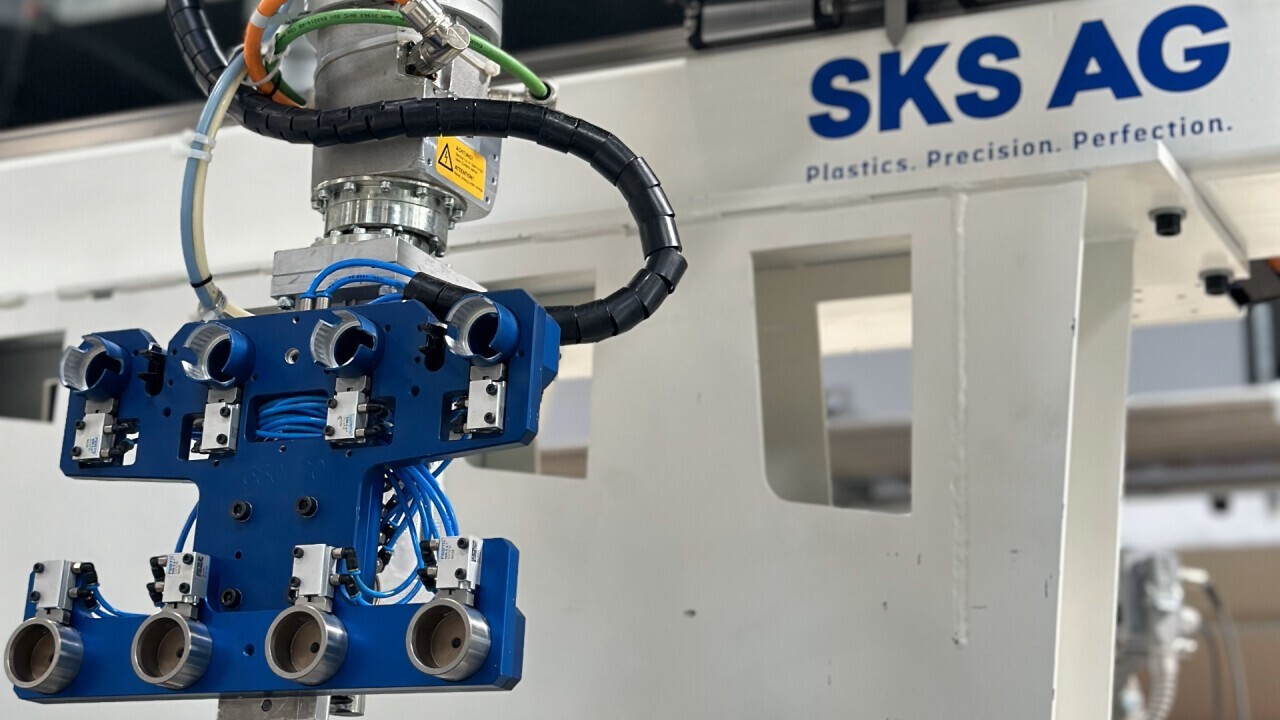

Half tool, production and assembly costs thanks to 4+4-fold and automation

The challenge: Two differently sized parts with threads in large quantities, which were assembled by hand. With our solution, we were able to reduce the costs a lot.