Service MedtecLIVE 2024

High-precision and fully automated stent production

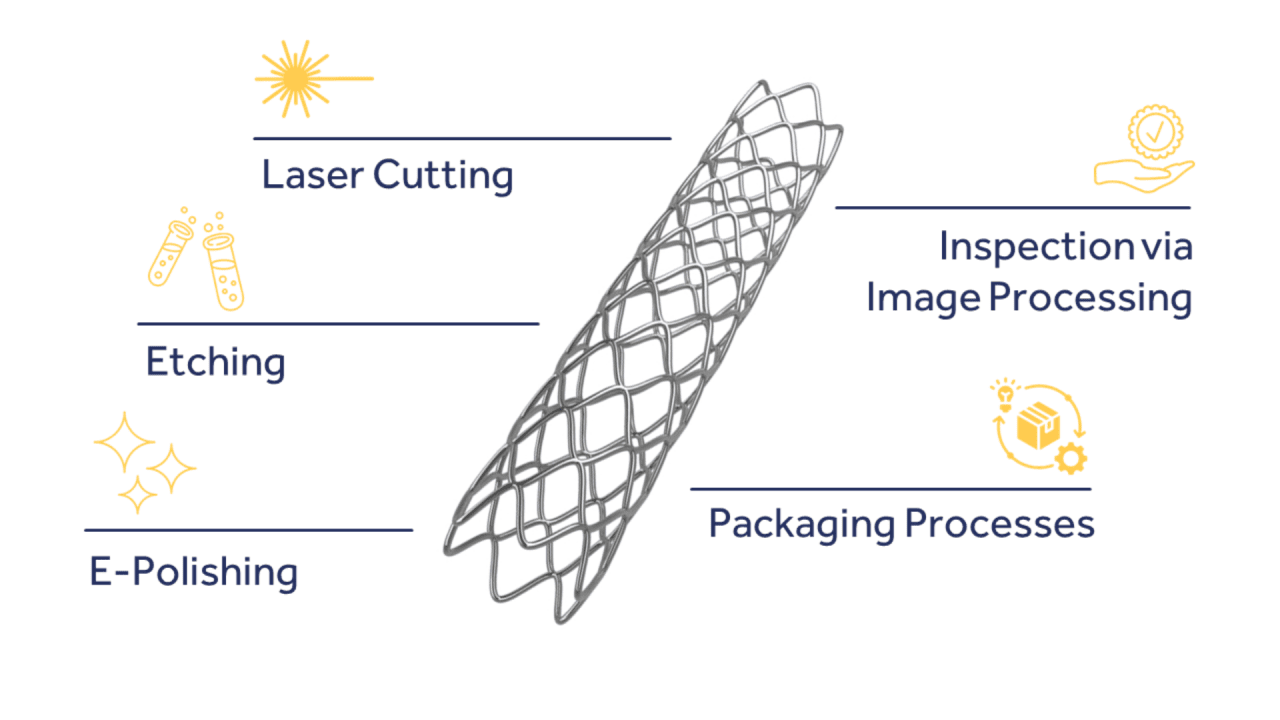

We support our customers at every step along the entire value chain. From the consistent quality of the stent surface to the reliable reproducibility of all product parameters - our teams deal with the respective customer requirements from the pFMEA process onwards.