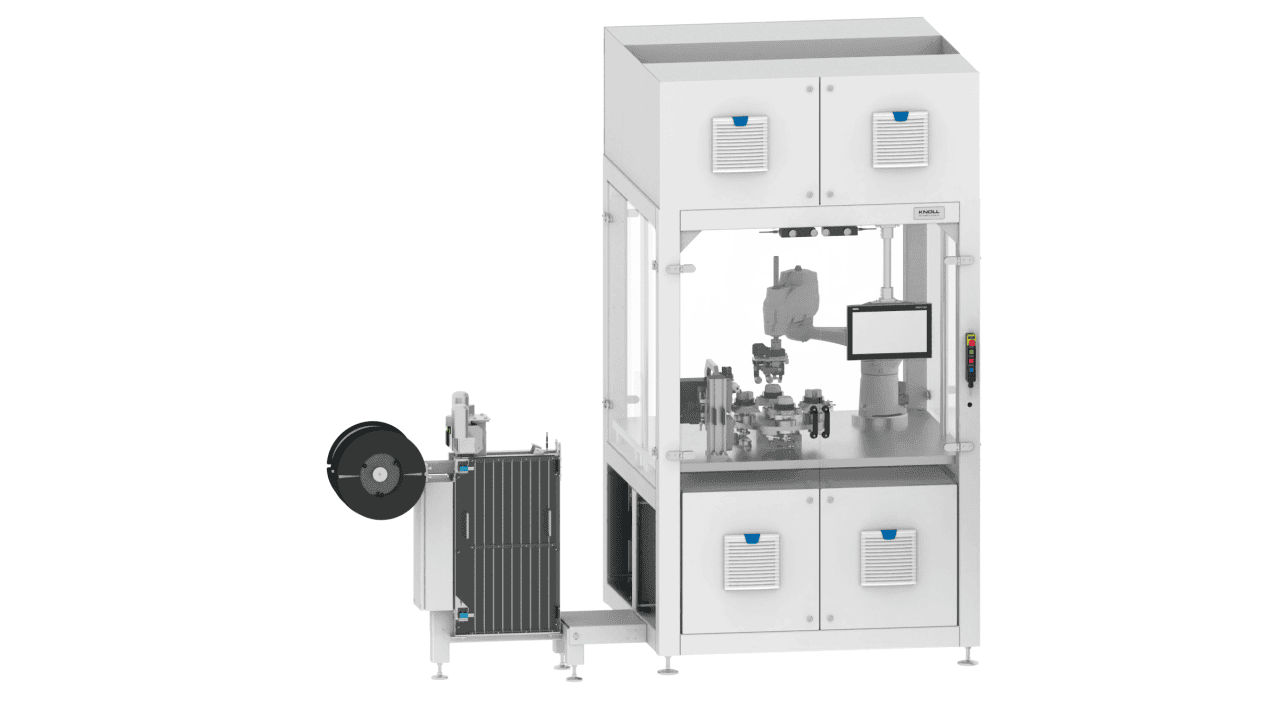

K-Test System: Solution for flexible and precise tubing assembly tests

The Ernst Knoll GmbH Test System enables individual, comprehensive testing and optimization of assembly processes and is designed to provide tailored evaluations.

Technical and Economic Benefits

The Knoll test system offers the option of flexibly testing individual or various process steps. The test facility represents our proven core technologies in a modular format. It enables processes such as handling and assembling flexible components, connecting tubes with other elements, conducting experimental series with customer-specific solvents, and determining cycle times.

Time Efficiency, Productivity and Reliable Test Results

Professional testing methodologies achieve consistently high quality and reproducible outcomes. Our customers benefit from over 65 years of experience and save valuable time in product development and quality assurance. Tests performed by qualified personnel ensure precise and reliable outcomes for actionable insights.

Determination of Optimal Process Parameters

TUBE STORAGE

Processes a variety of tube cross-sections and materials.

Unwinds coreless spools or rolls.

Gentle processing of the tubes.

FLEXIBLE GRIPPER TECHNOLOGY „HANDLING HEAD“

Adapts to various tube sizes and shapes.

Monitors gripping and assembling forces for secure handling.

Ensures secure and gentle testing.

Precise testing processes.

ROTARY TABLE WITH WINDING NEST

Customizable to your specific tasks and functional requirements.

Linking of individual processes.

Accurate positioning of tube ends for subsequent processes.

FEEDING SYSTEM

Precise feeding system for tubing and cables.

Ensures a gentle, low-tension transport.

Customizable adjustments to suit the conveyed medium.