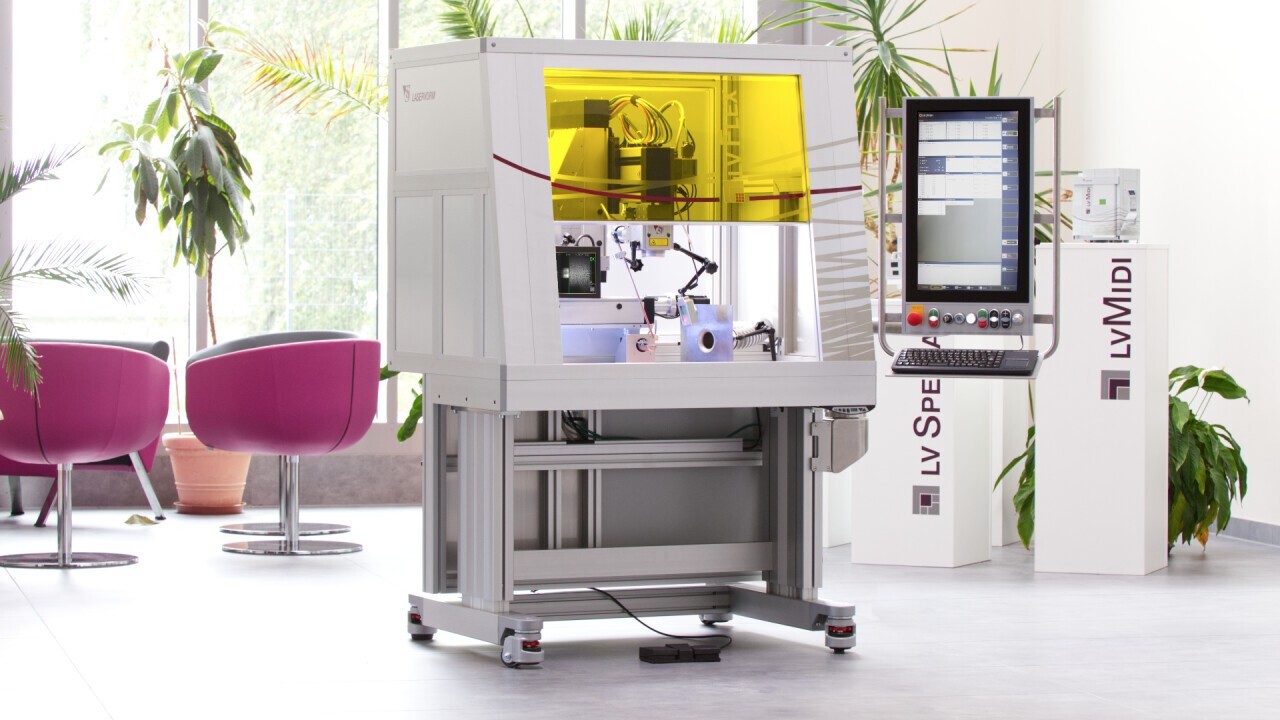

With the opening of MedtecLIVE today, LASERVORM presented a real innovation at booth 518b: the LV Flex. This machine combines CNC and manual laser welding in a unique form. But what makes the LV Flex really special?

The LV Flex is a compact, ergonomic CNC precision welding machine with up to five axes that enables both precise and safe manual welding. The machine can be converted from a fully automatic CNC system into a safe manual welding station in just a few simple steps. This flexibility makes it the ideal basic machine for medical technology manufacturers who need to handle a wide range of welding tasks.

Compact design for flexible applications

With dimensions of 895 mm x 1100 mm x 1700 mm and roller feet, the LV Flex fits easily through standard doors and can be used anywhere in "plug-and-play" operation thanks to its 230-volt safety plug. Its advanced laser technology works without cooling water and therefore requires very little power. An extremely versatile fiber laser, which can be operated continuously, pulsed and modulated with 15 to 1500 watts, enables precise laser welding on materials such as stainless steel, Phynox and titanium.

Ergonomic and practical equipment

The space-saving motorized lifting door made of laser safety glass and the ergonomic design of the door opening, which can be extended by a manual intervention element with minimal effort, ensure user-friendliness. The software automatically recognizes the use of the manual intervention element and switches the mode of use, making the workflow easier. A monitor-based observation solution ensures optimum visibility and precision during manual welding.

Sophisticated control technology

The LV Flex uses LASERVORM's proven control technology, which enables extremely precise machine control with a jitter of less than one microsecond. This ensures optimally synchronized laser pulsing, even during dynamic movements. Integrated logging and tracing functions facilitate monitoring and error analysis as well as traceability for market surveillance.

Flexible workspace and expandable options

The working area of the LV Flex is designed in such a way that even bulky or long, delicate assemblies can be welded safely. This represents a significant advance in terms of operator safety. The machine is equipped with a precise XYZ linear system and can be optionally extended with additional axes such as a rotary axis or swivel unit.

Ergonomics and user-friendliness

Another highlight is the ergonomic adaptability of the LV Flex. With spindle-driven lifting columns, the working height can be quickly adjusted and individual settings can be saved. This enables seamless switching between standing and seated workstations and significantly increases flexibility and user-friendliness.

Conclusion: A worthwhile investment

The LV Flex from LASERVORM combines a compact, robust and simple design with a wide processing spectrum. It offers a unique price-performance ratio and allows customers to benefit from the advantages of a precisely controlled CNC laser system while having the flexibility to safely weld small series and individual parts manually. This machine is a true innovation and an indispensable tool for the medical technology and precision engineering industries.