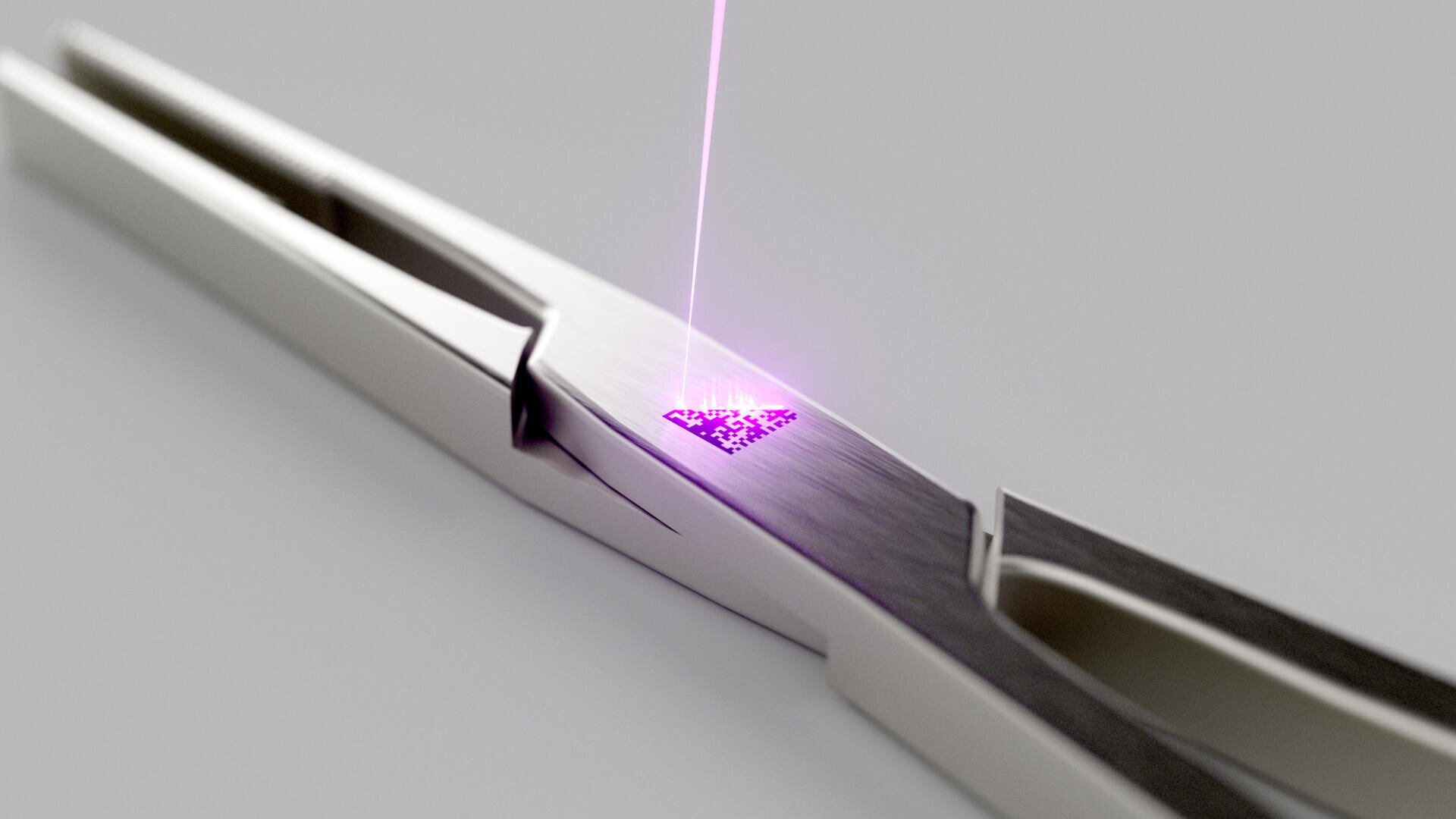

Ultra-short pulse laser for marking highly sensitive materials

Ultra-short light pulses in the picosecond range achieve outstandingly precise processing results on a micrometer scale. High-precision, low-damage material processing can be achieved with the ultrashort pulse laser.

Permanent marking and seamless tracking

For years, lasers have been firmly established for material processing and material marking in many industries. The advantages are obvious: lasers are ideal for very precise, intricate marking. In addition, neither paint nor solvents are required. This gentle and environmentally friendly process enables durable and abrasion-resistant material processing without the use of additives.

The traceability of products and protection against counterfeiting are also very important in the value chain. The laser tool is particularly suitable for marking. Laser markings, such as barcodes or 2D codes with information on serial or batch numbers and expiry dates, are created quickly and precisely by the laser beam in consistent quality on a wide variety of materials such as metal or plastic, thus ensuring seamless traceability.

The ultrashort pulse laser is used in particular in the field of medical technology, as there are very specific requirements here. For example, the markings must not cause any changes to the surface structure, as otherwise bacteria, viruses or pathogens can settle here. In addition, permanent sterilization processes severely attack the marking. Conventional marking processes using solid-state or fiber lasers, for example, lead to corrosion, peeling and fading of the marking. ACI offers the ultrashort pulse laser DFL Brevis Marker for this special problem. This is best suited to prevent material damage and the resulting corrosion and structural surface changes.

"Cold laser marking" for highly sensitive materials

With lasers in the nanosecond range, however, marking is always accompanied by strong heating of the absorbent material, which makes it difficult or impossible to mark sensitive materials without structural changes. With pulse lengths in the picosecond range, on the other hand, it is possible to achieve enormous pulse powers with low heat input. The pulse duration is so short that the inertia of the heat conduction is not sufficient to heat the surface strongly. In the best case, the area of the material on which the laser acts is transferred directly from the solid to the gaseous phase, so that burr formation is drastically reduced. The extremely low thermal influence is probably the greatest advantage of the ultrashort pulse laser. This "cold laser marking" makes a wide range of applications possible: the marking of highly sensitive materials in medical technology, sensor technology and aerospace. Furthermore, the shorter pulses cause less damage to the surrounding material and remove it more precisely, making very delicate markings possible. This is accompanied by increased detail accuracy, precision and surface quality.

Wide range of applications

The DFL Brevis Marker from ACI is particularly suitable for burr-free engraving on stainless steel, hardened steel, aluminum or glass. In addition, black markings can be made on untreated aluminium, stainless steel and HSS steel in a very short time and without prior surface treatment. The USP laser can also be used for color changes on plastic, marking silicones and cutting thin materials.