The laser marking solution for medical technology

The UDI guideline introduced by the FDA (Food and Drug Administration) requires medical products to be clearly labeled. This ensures traceability. Correct implementation is a concern for medical device manufacturers and raises a number of questions.

Why is UDI being introduced?

The UDI system enables:

- More efficient product recalls

- Better protection against counterfeiting

- Simplification of data entry and accessibility in different systems

- Security throughout the supply chain

- Safety corrective actions in the field (Field Safety Corrective Action - FSCA)

- Better identification, documentation and prevention of incidents

- Reducing the likelihood of medical errors

In addition, the labeling system supports the simplification of logistics, ordering and delivery processes.

What is the aim of the UDI system?

The main objective of the UDI system is to increase patient safety and ensure sustainable traceability of products. The FDA directive applies to medical devices that are manufactured in the USA, imported or distributed on the US market. Similar regulations also apply internationally: the European Union has introduced UDI requirements as part of the new MDR (Medical Device Regulation), which will be gradually implemented from 2020.

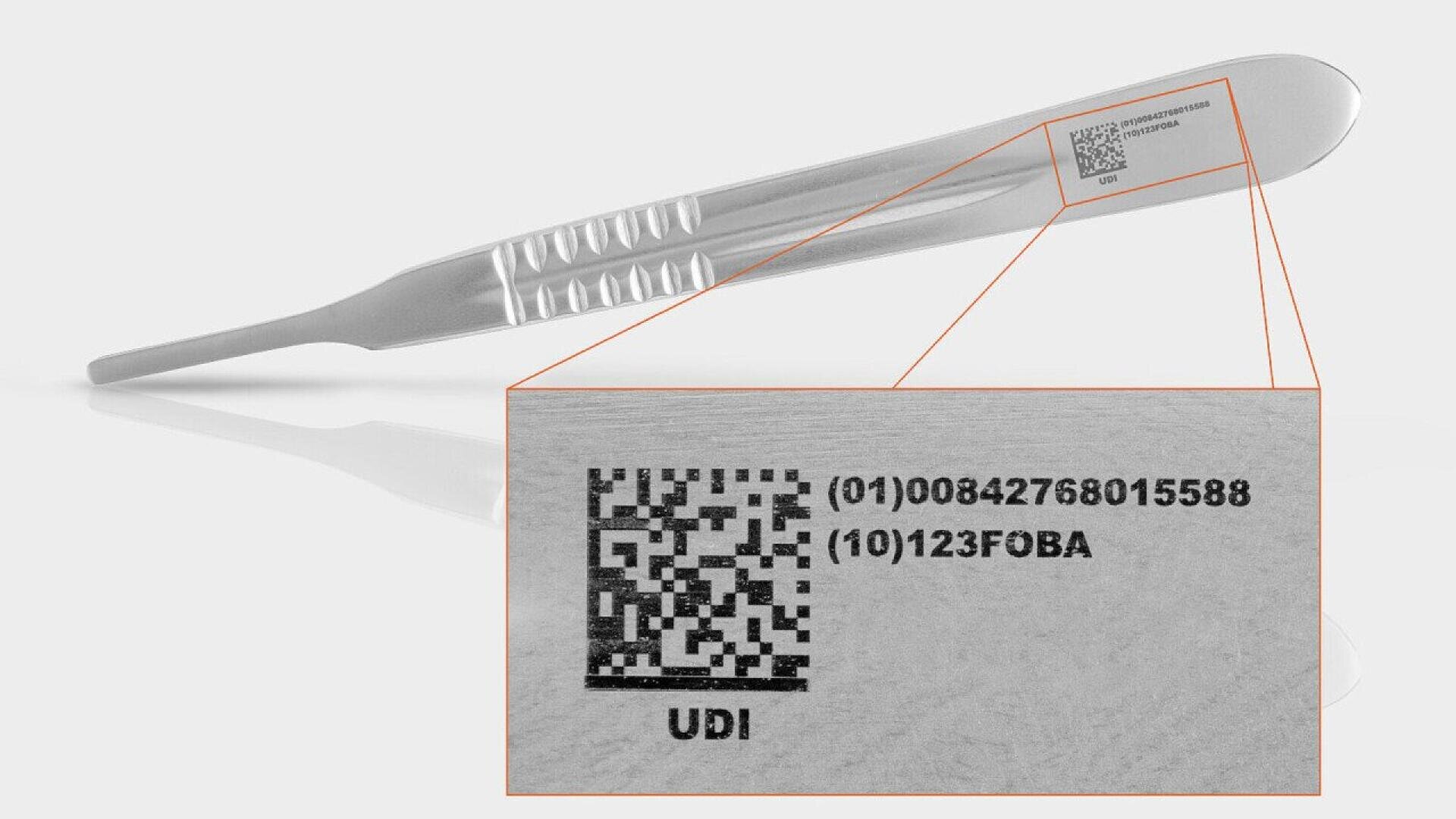

How is a UDI code structured?

UDI codes are represented graphically in a combination of two elements: A sequence of clearly legible alphanumeric characters and a machine-readable code. The different machine-readable codes are the GS1-128 linear barcode and the GS1 Datamatrix code, the HIBC linear barcode and the HIBC Datamatrix code, as well as the linear ISBT 128 and 2D code of the ICCBBA. Depending on the respective issuing authority, each product receives its own code in one of the code formats mentioned.

Which process is suitable for marking UDI codes?

The implementation of suitable technology for UDI direct marking faces challenges, as the FDA does not prescribe a specific method. The choice is difficult because not every process meets the UDI requirements. Laser marking proves to be the optimal solution - it meets all the criteria for secure product marking according to medical standards and UDI. Camera-based laser marking devices also offer economic and reliable advantages in the marking process.

Visit our website to find out how dental implants are labeled.