Best practice MedtecLIVE 2024

Precision round bars enable a high degree of automation

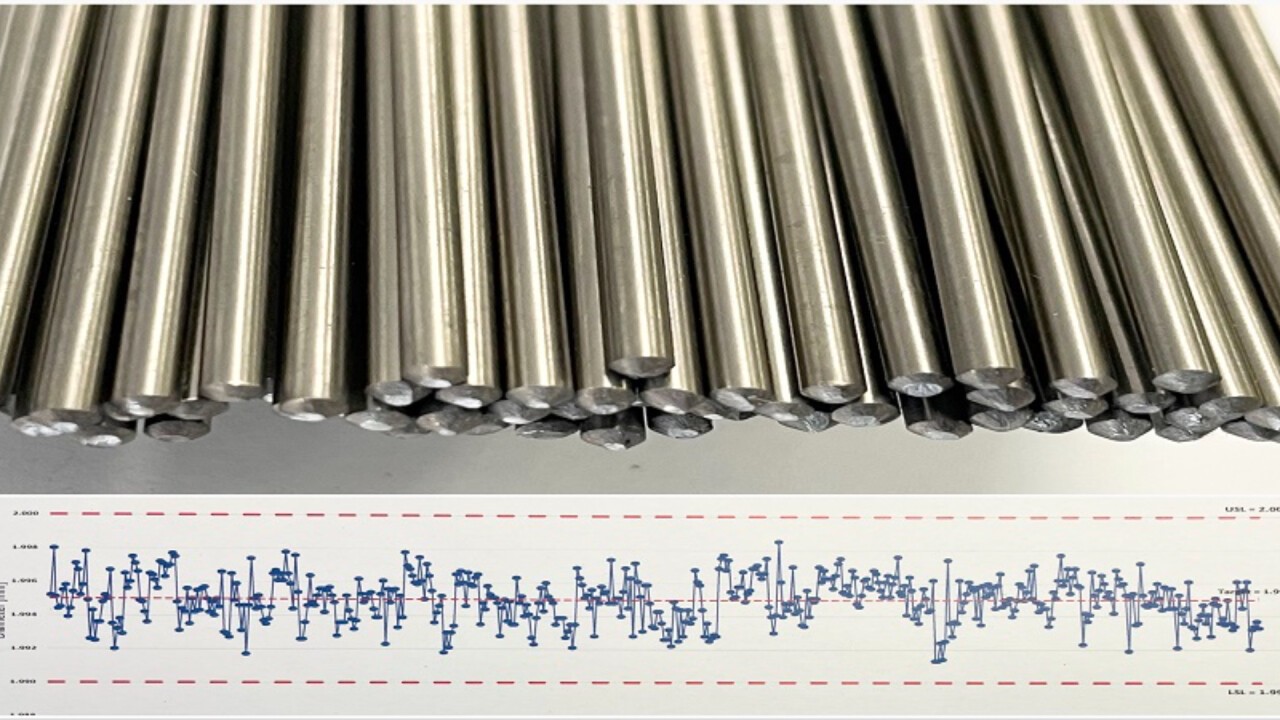

Signer Titanium offers precision round bars made of titanium and titanium alloys that meet the highest requirements with tolerances in the h6 and h5 range for diameters from 1.5 mm to 8 mm